a sustainable solution

travelling 4,500 km by airplane or 70,000 km by train*.)

*Source:

Severe structural damage from uncontrolled collision and derailment incidents can be avoided by using Green Buffers’ system.

It enables the reuse of existing equipment and materials, reducing the need for new production, thus lowering negative climate impact.

For example, about 400 tonnes of CO2e per coach can be saved when a coach can be used immediately after a collision instead of having to manufacture a new one. This is approximately the same amount of CO2e caused by one person travelling 45 laps around the globe by airplane or 670 laps around the globe by train.

But it doesn’t stop there - GREEN BUFFERS' system is also:

Lightweight

The buffer system is made of STRENX®, high strength steel. This makes the product lighter and stronger, affecting the weight of the entire train set.

Traceable

Green Buffers cloud service offers, together with smart innovations from our partners, full traceability of the product materials – from the metal ore in the mine to the final steel product after assembly.

Recyclable

After a collision, the affected components can be easily disassembled from the train and sent back for recycling through their unique marking system. This contributes to reduced material consumption and a sustainable supply chain.

Scalable

Since the system can be used on both existing and new trains, the lifetime of trains currently in operation can be extended, but with increased safety.

Equal

Irrespective of the country or class in which you are traveling, Green Buffers offers you the right to the same safety standards.

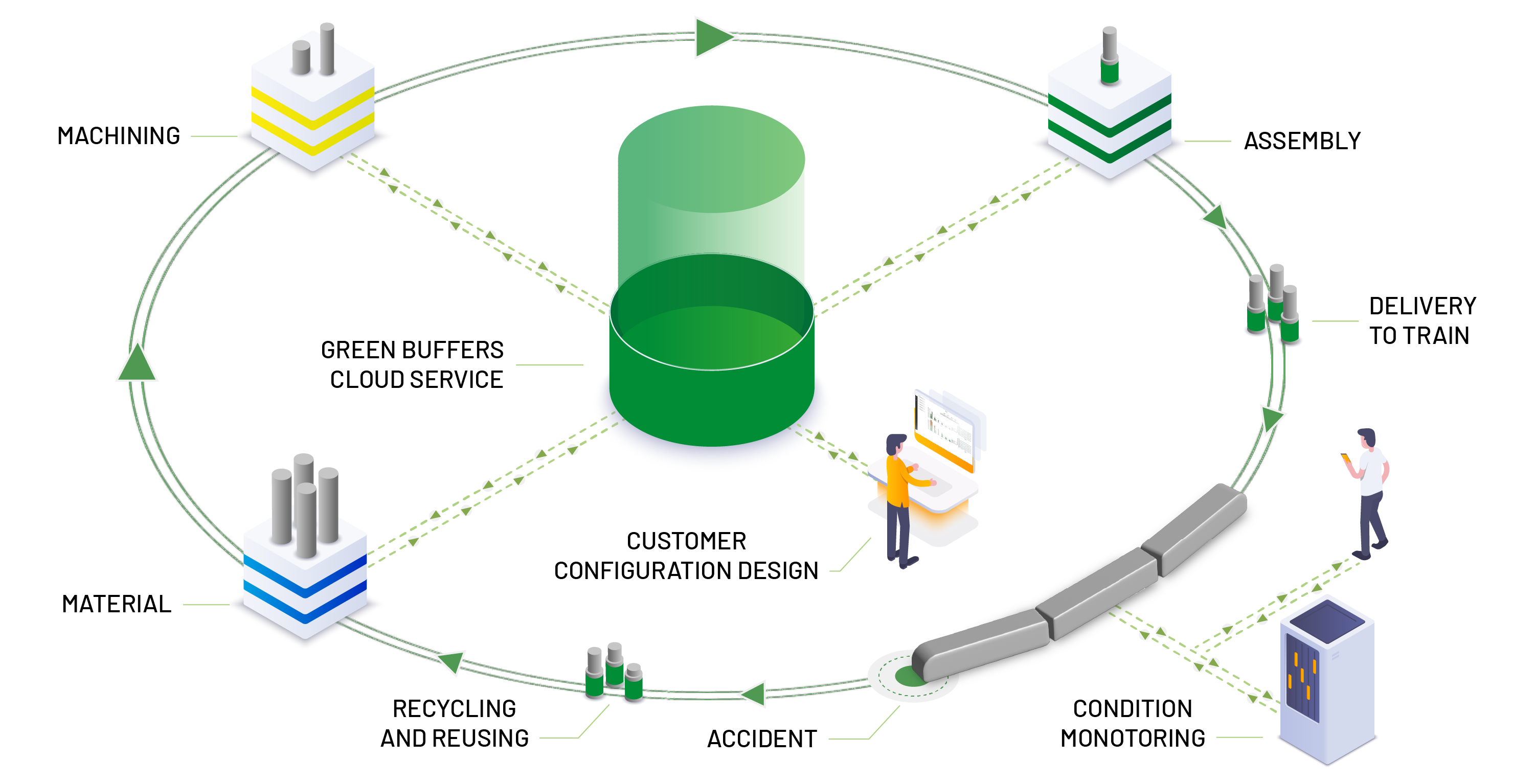

circular supply chain on track for you

totally DIGITALIZED

all processes:

DESIGN

PRODUction

DISTRIBution

CONSUMption

CONDITION MONITORING

RECYCLing

GREEN BUFFERS Cloud Service

By having an easy to use Cloud service with configuration design, it is possible to fully digitize the entire supply chain – from first customer input to delivery and installation or re-installation on trains.

Green Buffers modular product process can be easily adapted to the customers´ development process and the site then seamlessly connects both supplier and customer for optimized planning and operation. A circular supply chain is fully implemented.

The cloud service is a transparent information site adapted for each train project – both for new applications and for upgrades of existing trains.

The integrated condition monitoring system provides an on-line status of each individual buffer. This greatly reduces train down time after a collision.

Green Buffers embraces the Global sustainable development goals, focusing on three goals.

Goal #3

To work for safe products and services.

Goal #9

The very core of our business is that we do something new that can save lives.

goal #12

Product traceability is an important part of consumption. Industrial and urban symbiosis include information flows, inventory and energy use.